A CNC Tube Bending Machine is an advanced, automated pipe bending machine that uses Computer Numerical Control (CNC) technology to execute highly precise bending of tubes and pipes. As a form of tube bending equipment, it combines mechanical, hydraulic, electrical, and software systems to perform complex bending operations following pre-programmed instructions. These machines are essential in industries that demand high-precision tube forming such as aerospace, automotive, and medical device manufacturing.

Whether you’re working with stainless steel pipes, aluminum tubing, or copper coils, CNC technology ensures accurate, repeatable bends—making it a trusted solution among metal tube bender applications.

Key Features & Capabilities

Precision: Achieves bend angles with accuracy up to ±0.1°, ideal for demanding systems like aerospace hydraulic tubing.

Material Compatibility: Suitable for metal tubes (e.g., stainless steel tube bending, aluminum tube bending, copper pipe bending), plastic pipes, and composites.

Diameter Range: Typically processes tubes from 3mm–300mm, depending on model.

Common Applications:

Automotive exhaust and brake lines

Furniture frames with complex bends (90°, 180°, spiral)

Architectural handrails and medical devices

From manual pipe benders to automatic CNC pipe benders, the technology adapts to various sectors requiring precision and efficiency.

Types of Tube Bending Machines

1. Manual Tube Benders

Features:

Operated using hand force or crank.

No digital control—relies on molds or visual guesswork.

Pros: Cost-effective, lightweight, and portable.

Cons: Low accuracy (±5°), only suitable for basic, single-bend tasks.

Manual benders are ideal as an entry-level pipe bender tool but not suitable for industrial or multi-bend needs.

2. Automatic CNC Tube Benders

(1) Hydraulic CNC Pipe Benders

Drive System: Hybrid—combines hydraulic and servo motors.

Features:

Delivers bending forces up to 200 tons.

Designed for large-diameter applications (e.g., Φ150mm+).

Moderate precision (±0.2°); performance can be influenced by oil temperature.

Best For:

Heavy industries: Thick-walled tubes like Φ200mm×10mm.

High-volume production: More stable than manual or semi-auto systems.

The precision hydraulic pipe bender machine is the go-to solution for large tube diameters and applications like truck chassis and industrial pipelines.

(2) All-Electric Servo CNC Benders

Drive System: 100% servo-electric.

Features:

Ultra-precise (±0.05°), high-speed (60°/sec+), and oil-free.

Suited for clean room operations (medical, electronics).

Limitations:

Max torque often ≤50 tons.

Less effective on thick-walled tubes over Φ80mm.

Typical Uses:

Automotive brake lines (Φ6mm SS)

Aerospace titanium tubes (dynamic springback control)

For industries requiring silent operation, minimal maintenance, and hygienic environments, electric pipe bending machines and electric tube benders are ideal.

General Selection Advice

Cost-effective, large-diameter tubes → Hydraulic CNC pipe bender

High precision & clean environment → All-electric servo CNC tube bender

Thin-wall tubes (≤0.3mm) → Servo + mandrel bender (anti-flattening)

For specialized needs, consider a mandrel pipe bender or mandrel tube bender, particularly in high-performance applications.

Mandrels: Types & Functions

A mandrel is a key component in advanced tube benders and pipe bending machines. It prevents defects like wrinkling, thinning, or ovalization during bends—especially important for thin-walled stainless steel, aluminum tubes, or titanium pipes.

Key Mandrel Functions:

Maintains roundness (supports the inner wall).

Reduces wrinkles (inner radius support).

Controls wall thickness (avoids cracking on the outer arc).

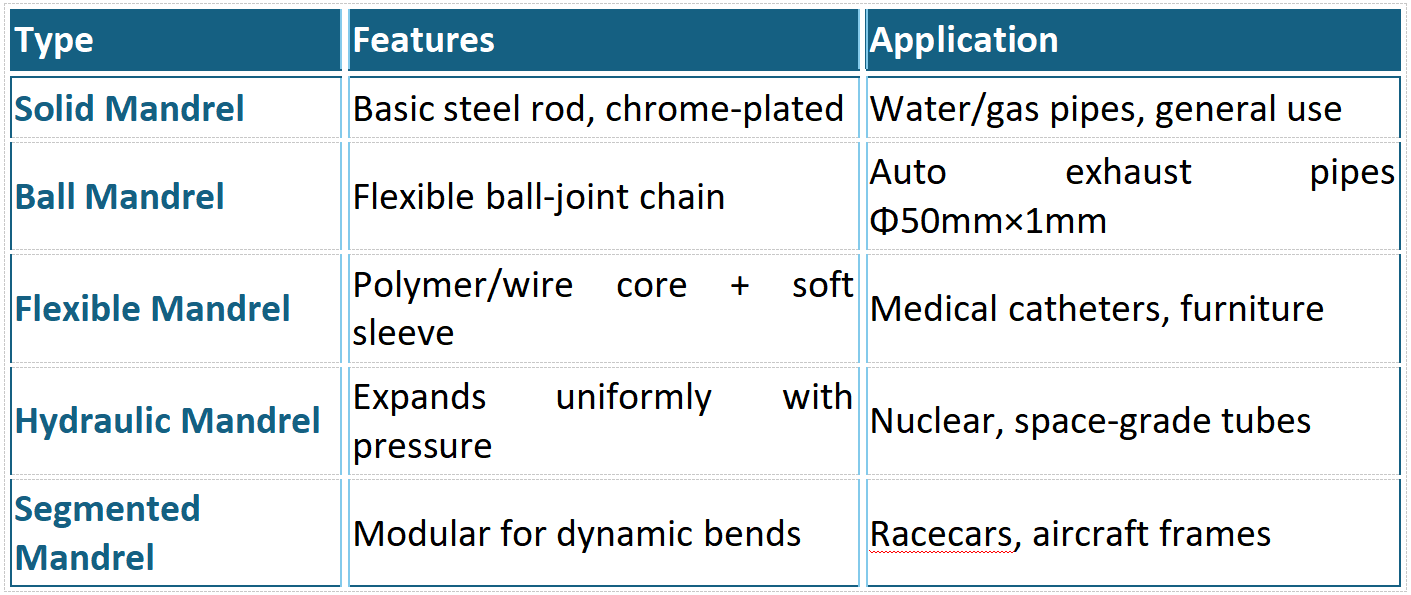

5 Mandrel Types & Best Use Cases:

Usage Tips:

Use lubrication: Reduces friction up to 30%.

Ensure dynamic retraction to prevent cracking.

Replace if wear >0.5mm to maintain accuracy.

Applications of CNC Tube Bending Machines

1. Automotive

Exhausts: Precision exhaust pipe benders used for S-shaped and 3D curves (e.g., BMW M-series).

Brake Lines: Stainless steel tube benders craft complex multi-bend brake tubes.

Chassis Bending: High-strength steel (e.g., DP800) with compensation for springback.

2. Aerospace

Hydraulic Tubes: Titanium (Φ10mm×0.5mm) using CNC pipe benders with ±0.05° precision.

Fuel & Cooling Lines: Aluminum and Inconel, tested with laser roundness tools.

3. Appliances & Electronics

AC Tubing: Copper pipe benders create U-shapes at high production rates.

Laptop Heat Pipes: Ultra-thin (Φ3mm×0.2mm) copper bent via vision-guided CNC.

4. Energy & Chemical

Oil & Gas Pipelines: Φ200mm×10mm carbon steel, API 5L-compliant.

Nuclear Applications: Polished SS316L (Ra≤0.8μm) using stainless steel pipe benders.

5. Medical

Surgical Robots: Bending Nitinol wires (Φ2mm) with ±0.02mm precision.

Dialysis Equipment: Uses automatic pipe benders for kink-free PVC tube bending.

6. Furniture & Architecture

Chair Frames: Steel tube benders forming smooth biomimetic curves.

Handrails: Spiral stainless steel formed with multi-axis CNC tube benders.

7. Emerging Trends

EV Battery Cooling: Aluminum serpentine bends (20×5mm) with anti-flattening tooling.

Superconducting Coils: Niobium-titanium tubes bent for cryogenic systems.

Conclusion

From exhaust pipe benders in high-performance vehicles to mandrel tube benders for aircraft hydraulic systems, CNC tube and pipe bending machines represent the backbone of modern metal shaping technologies. Whether you’re in automotive, aerospace, energy, or medical sectors, there’s a precision tube bender solution for you.

Need a Custom Tube Bending Solution?

Contact SLS Machinery—a global leader in pipe bending equipment and CNC tube forming technology.

Contact: SLS Machinery

WeChat/WhatsApp/Phone: +86-181 0015 0701

Email: info@slsmachinery.com

Address: Zhangjiagang City, Jiangsu Province, China.

Website: www.slsmachinery.com

Disclaimer: The views, suggestions, and opinions expressed here are the sole responsibility of the experts. No Graph Daily journalist was involved in the writing and production of this article.